The Merlin workshop is always a busy place, head honcho, Lee, shares the most common bike issues to roll through the workshop door.

Read his ‘Secrets’ to keep your bike running smoothly…

Seized / Snapped components

A tiny dab of grease can go a long way. Watch out for the usual victims of seizing / galling; pedals, seatpost, bottom bracket cups. Grease is inexpensive but can save a whole load of heartache and skinned knuckles in the future. If its got a thread – grease it!

Snapped components usually happen because of bad maintenance. Snapped gear cables usually occur because of two issues. Either the routing is not ideal / the cables have too much friction, or the entry into the outer cable is unsealed (allowing weather / grit to get in). When fitting components, stick to manufacturers torque settings or fit using a torque gauge if you are not sure.

TIP: Use the right lubrication to fit each component

Disc Brake Maintenance

Brakes which need bleeding, split / leaking hoses or worn pads are the usual culprits with disc brakes. However, also seen pretty regularly is contamination of rotors / pads with things like chain oil which can soak into the pad and badly affect performance.

TIP: Make sure disc rotors are covered if you like to spray ‘wild and free’ with your degreaser or chain oil.

Drive Train Wear

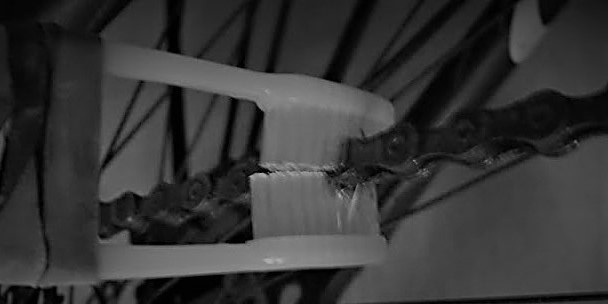

Neglecting to de-grease and lube your chain is a sure-fire way to get a prematurely worn drive train. De-greasing and lubing need to be done in that order, just adding more chain oil will result in a gloopy inefficient chain. The degreaser cleans the old oil and dirt off the chain, the chain oil re-coats the chain in lubrication all ready for the next ride.

TIP: If you don’t have a chain cleaning brush, two old toothbrushes taped together (brush to brush) can make a great chain cleaning tool. Just don’t use them for teeth again…

Creaking Bottom Brackets

Bottom brackets tend to make noise when they get towards the end of their life. If you are replacing your own bottom bracket, clean the thread after the bottom bracket has been removed, then apply a little grease to the clean threads. This will allow the bottom bracket to be fitted easier and removed again at the end of its life.

TIP: When fitting hollowtech 2 cranks to the bottom bracket, use the pre-load adjuster delicately to take out any play in the cranks, before tightening the cranks. If the pre-load adjuster is fully tightened, the bearings will wear quicker.

Buckled Wheels

Wheels cope with a lot before they go out of shape. Get into the way of regularly checking that wheels are true. Lift the front or rear of the bike in the air and spin the wheel. Watch the gap between the rim wall and the brake block – if the wheel is not true the distance between the block and rim will vary. Small buckles – between than 2-5mm need to be trued or regularly checked until they can be fixed. If they get worse or if the buckle is worse than 5mm – it is definitely time to true the wheel. Buckled wheels tend to get worse of time.

TIP: Regularly ride roads which are in terrible condition? Ride the fattest tyres your frame will allow and drop your tyre pressure by 10 – 15% from the maximum, the extra cushioning ride should protect you wheels and give a more comfortable ride.

Worn Brake Blocks / Pads

Brake pads usually wear out quicker if the bike is used in bad conditions. Grime / mud / filth get ground between the pad and the rim or rotor and cause wear more quickly.

conditions. Grime / mud / filth get ground between the pad and the rim or rotor and cause wear more quickly.

TIP: Check pads / blocks regularly – make sure there are no fragments of flint / stone / metal ground into the pad. These will score rims and can cause serious damage.

Punctures

Keep checking tyres regularly, while small cuts in the outer rubber of the tyre might be okay, larger cuts can be dangerous. If your bike regularly covers rougher roads or urban areas, check for flints / glass embedded in the tyre. The best way to avoid punctures is to change your tyres before they get completely worn out. While it is possible to ride modern tyres down to the casing, it’s not advisable as the casing offers no grip whatsoever.

TIP: Try to ride around sharp stuff which will hurt your tyres!

Headset Worn

Headset bearings eventually wear out. The best way to minimise wear is to adjust the headset through its life. If a little bit of play becomes noticeable, fix it with the load adjuster / top cap. If the headset isn’t correctly adjusted the play will progressively get worse.

TIP: Test for play in the headset by holding the front brake on and trying to rock the bike backwards and forwards. If there is play in the headset it will need adjusting.

General Lack of Maintenance

Bikes which have been neglected tend to show the same issues, usually a mix of those highlighted above. The best way to avoid maintenance issues is to keep your bike clean and lubricated.

TIP: Caring for your bike, will give a ‘heads up’ on any future issues which could make themselves apparent in weeks to come.

Mysterious & unexplained noises

Those mysterious noises which bikes make from time to time are usually down to neglect – yes, it’s a cry for help.

TIP: Check out our blog from earlier in the year to help pinpoint that unexplained noise…

❤LOVE IT!❤

The fastest way to make a bike un-roadworthy, is to just ride it with no maintenance or care whatsoever. One common mistake is to think that more expensive bikes, can handle more abuse.

After every ride have a look at your bike. If conditions were nasty, give your bike some love. A wash, check over, de-grease & lube of the chain & cassette, will usually be enough to keep your bike happy & rolling.

Check out our range of bike cleaning products here and bike maintenance tools here.

Top 10 – Merlin Tools

Check out our own high-performance / low-cost tool options below. Click link for full details.

Merlin 20 Piece Tool Kit £44.95

Merlin Bottom Bracket Tool £10.00

Merlin Chain Checker Tool £5.99

Merlin Allen / Hex Key Set £4.99

Merlin Tyre Levers £1.99

Merlin Quick Link Tool £14.99

Merlin Cable Cutters £9.95

Merlin Cassette Tool £7.99

Merlin Chain Whip £7.99

Merlin Pro Chain Tool £19.99